Tools Required:

Fine Sandpaper

Pliers (Round Nosed)

Wire cutters

5/32" aircraft length Drillbit/Battery Drill |

Additional items required:

Sealer

Paint

5 minute Epoxy |

| Step #1 |

Using 5 minute epoxy apply to the

belly weight and install into hole on bottom of lure-one weight in the

furthest front hole and one weight in the furthest rear hole. Leave lure upside down until dry. Optionally fill belly

hole with wood putty after weights are glued in and sand flush if

necessary. |

Pictures coming soon! |

| Step #1A |

Using an extended length 5/32"

drill bit and very low speed, carefully drill the through-wire hole

through the lead weights previously installed. Be very careful here and

go slow so as not to let the lure go out of control and result in

injury. |

|

| Step #2 |

If necessary, lightly

sand lure with fine grit sandpaper to a maximum of 220 grit. |

|

| Step #3 |

Using 5 minute Epoxy,

glue the belly grommet into the middle hole in the belly of the lure,

leave lure upside down until epoxy is dry so it doesn't run out. |

|

| Step #4 |

It is highly

recommended you seal the lure against water penetration to prevent the

lure from splitting if it absorbs water. This can be done with simple

Shellac or a 60/40 mix of boiled linseed oil and mineral spirits.

Observe caution and proper disposal of any rags used. Allow to dry fully

before proceeding further. |

|

| Step #5 |

Prime and paint lure,

several options exist-AC Moore has Cracker Barrel latex paints available

inexpensively and these can be used with a small brush. This is a good

choice if the lures are to be made by children. Alternately the lure can

be be painted with spray paint available from any hardware store. Bin

primer is a good choice to prep the lure for paint. Follow all

precautions with use of these items. |

|

| Step #6 |

After the lure is

painted we recommend you spray with a minimum of two coats of Clear

spray paint or brush with Spar Varnish to protect the paint from rocks

and sharp fish teeth. Allow to dry fully before handling. |

|

| Step #7 |

Using 5 minute epoxy,

Glue eyes in the recessed areas on the side of the lure at this time. Allow to dry fully before handling. |

|

| Step #8 |

Insert small 3/16"

nose grommet into the front of the lure. |

|

| Step #9 |

Insert through wire

into front of lure through the nose grommet until you see the wire just

inside the belly hook hole. |

|

| Step #10 |

Take 150 lb swivel and

insert into the belly hole while pushing the wire through the

through-hole. The idea is to captivate the wire through the open end of

the swivel inside the lure so just the bottom loop of the swivel is

accessible on the bottom of the lure. |

|

| Step #11 |

Push the wire all the

way into the front of the lure so that the tag end of the wire is inside

the nose grommet. The wire will extend out the back of the lure. Line up

the nose loop up and down on the lure. |

|

| Step #12 |

Install Large tail

weight over the wire and insert into the rear of the lure. |

|

| Step #13 |

Insert the post style

tail grommet over the wire and insert into the rear of the previously

installed weight. |

|

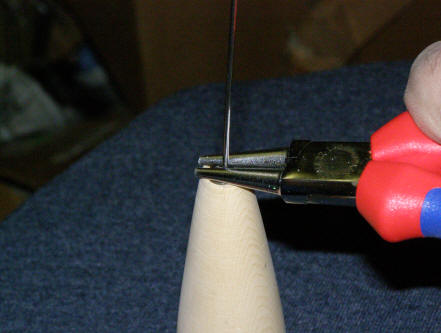

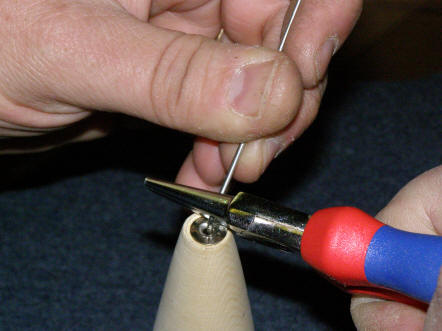

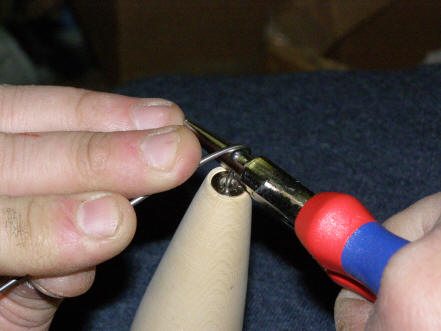

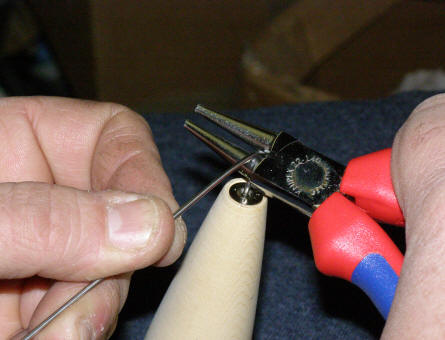

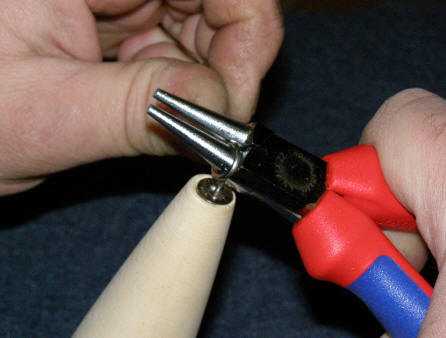

| Step #14 |

Wrap the wire into a

loop on a pair of round nose pliers, or use a nail in a vise to bend the

wire into a loop. Then wrap the wire around itself to tighten the

through wire and "pre-stress" the wire inside the lure. |

|

| Step #15 |

Install 3/0 Treble

belly and tail hooks using #5 split rings (Split rings and hooks not

included in kit) |

|

| These

instructions detail very basic assembly/finishing techniques for this

lure, more information and lure finishing tips can be found on the

www.striped-bass.com lure forum or utilize the search feature on the

forum. |